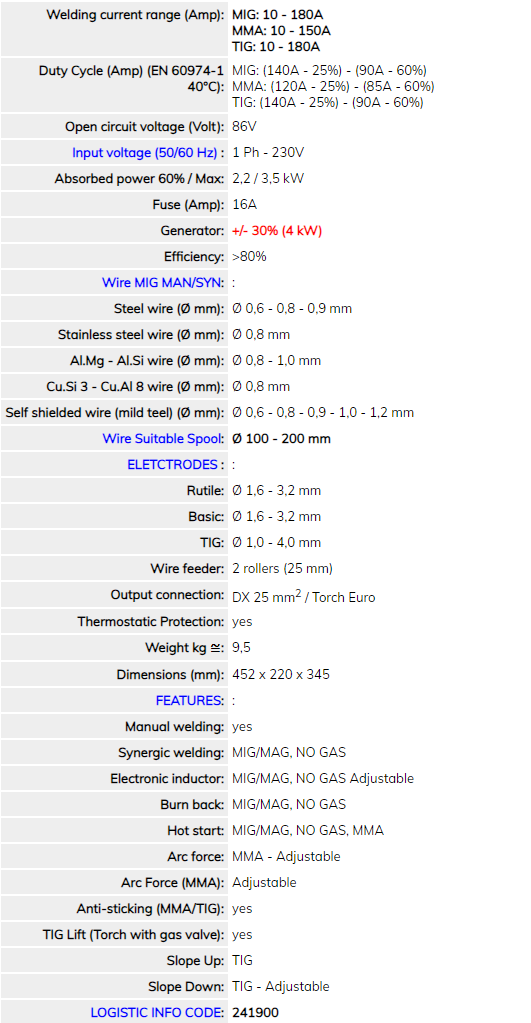

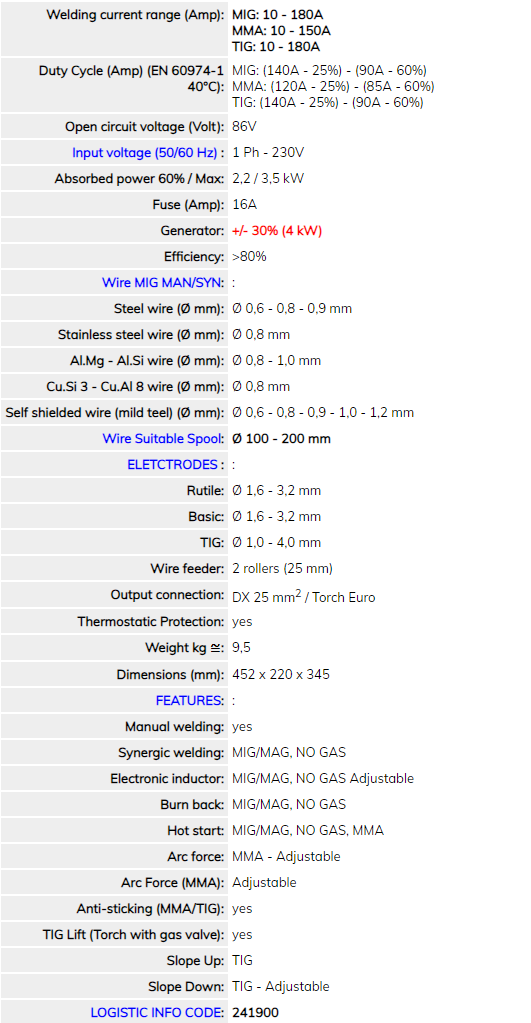

Welding machine MIGA 218 230V/3.50kW 10-180A inverter DECA 241900

SKU

27610124

Availability:

On order

VAT will be added to the product price.

Inverter technology power source controlled by microprocessor for MIG/MAG, et wire NO-GAS, MMA and TIG DC welding

Equipment: MIG torch 180A 3m EURO (Nozzle Ø 1.0 mm), rollers (Ø 0.8 / 1.0 mm Fe), 16 mm2 cable with mass clamp (2 m), gas hose (1, 5 m).

The MULTIPROCESS inverter welding generators of the MIGA line are versatile, very simple to use but with a welding quality usually found in more sophisticated products. The MIGA line is the right quality/price ratio for those who have to carry out maintenance work, small constructions and workshop work. A reliable and durable product, carefully designed and manufactured at our factories in San Marino.

The exclusive EASY MIG FULL SETTING interface allows you to weld in Synergic MIG / Manual MIG / WIRE No Gas / MMA / TIG Lift.

In synergic MIG mode it makes welding of many metals such as: steel, stainless steel, aluminum and brazing with copper silicon or copper aluminum wires simple.

In MMA mode it allows welding of rutile and basic coated electrodes.

In TIG Lift mode it is perfect for precision work.

The MIGA 218 model delivers 180 Amp in direct current. Accommodates 100mm and 200mm diameter wire spools. The MIG torch is with EURO quick coupling.

Through the main FULL SETTING command, in addition to selecting the welding process, it is possible to adjust other important parameters to always obtain an excellent result. The main features of the MIGA series are:

- Synergic MIG: extremely simple system adjustment.

- MIG Inductance Adjustment: ("Full Setting" command) it is possible to adjust this value to reduce welding spatter.

- Adjustable MMA Arc Force: ("Full Setting" command) to obtain optimal welding with each electrode it is possible to adjust the temporary increase in current when the electric arc becomes short.

- MMA Automatic Hot Start: facilitates the striking of the bow.

- TIG LIFT: the arc is struck by touching the piece with the electrode and lifting it slowly. The risk of contaminating the workpiece with the tungsten electrode is modest.

- Automatic TIG slope up: progressive increase in welding current to obtain an impeccable start of the welding seam.

- Adjustable TIG Slope down: ("Full Setting" command) decrease in welding current to obtain an impeccable end of the welding bead.